Dive into the world of the latest smart robotics in manufacturing with a captivating overview that sheds light on the innovative technology shaping the industry. From revolutionizing traditional processes to enhancing efficiency, this introduction sets the stage for an insightful exploration.

In the realm of manufacturing, smart robotics are paving the way for a new era of automation and precision. As industries evolve and adapt to the changing landscape, the incorporation of smart robotics is becoming increasingly prevalent, offering a glimpse into the future of manufacturing processes.

Overview of Smart Robotics in Manufacturing

Smart robotics in manufacturing refers to the use of advanced robotic systems equipped with artificial intelligence and automation capabilities to streamline production processes and improve efficiency in manufacturing facilities.

This technology is revolutionizing the manufacturing industry by enabling companies to automate repetitive tasks, enhance precision and accuracy, increase productivity, and reduce operational costs.

Benefits of Smart Robotics in Manufacturing

- Improved Efficiency: Smart robotics can work around the clock without breaks, leading to increased production output and faster turnaround times.

- Enhanced Precision: Robots can perform tasks with high accuracy, reducing errors and waste in manufacturing processes.

- Cost Savings: By automating routine tasks, companies can save on labor costs and minimize operational expenses.

- Safety: Smart robotics can handle hazardous or strenuous tasks that may pose risks to human workers, ensuring a safer work environment.

Industries Leveraging Smart Robotics Technology

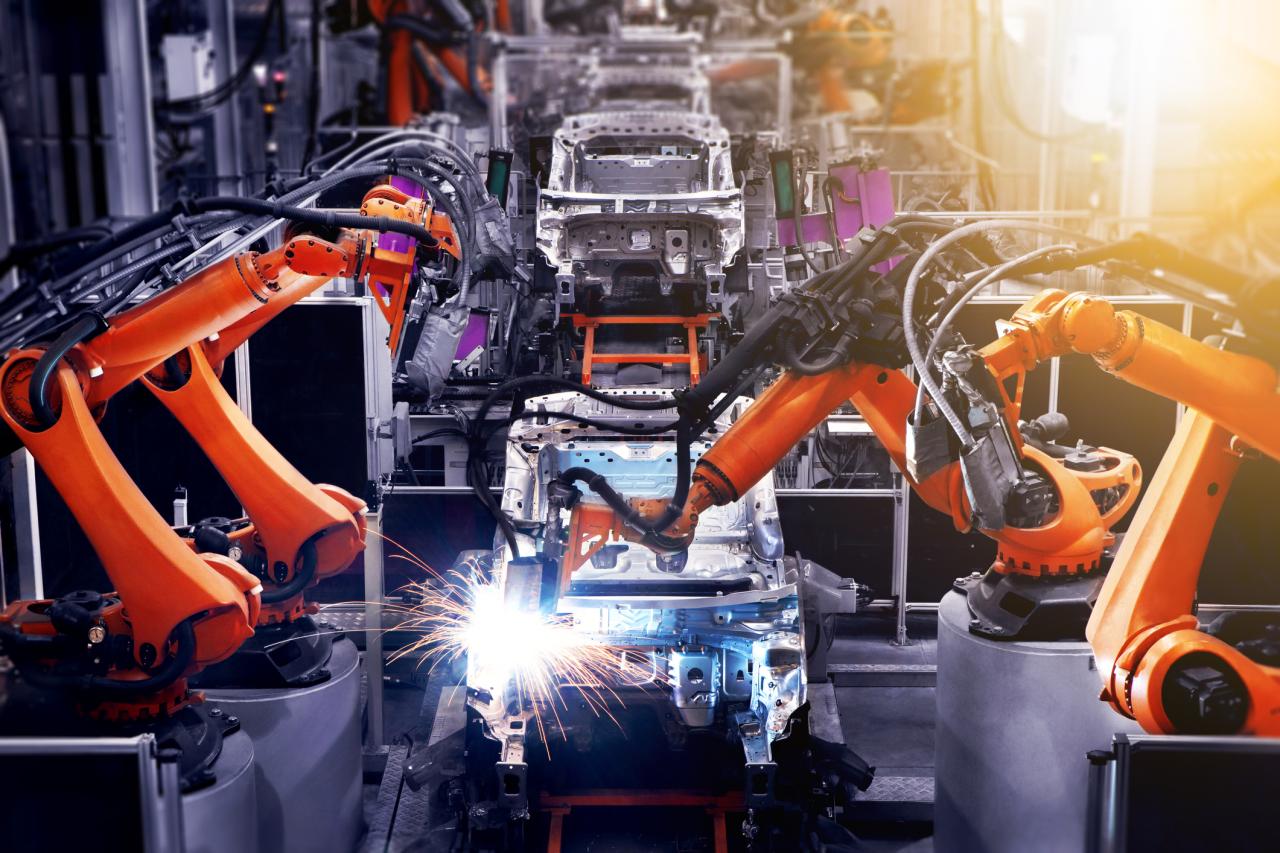

- Automotive: Car manufacturers use smart robotics for assembly line tasks such as welding, painting, and quality control.

- Electronics: Electronics companies utilize robotics for circuit board assembly, soldering, and testing processes.

- Pharmaceuticals: Pharmaceutical companies leverage smart robotics for packaging, labeling, and quality assurance in drug manufacturing.

Applications of Smart Robotics in Manufacturing

Smart robotics have revolutionized the manufacturing industry by offering a wide range of applications that enhance efficiency, accuracy, and productivity on the manufacturing floor.

Automated Assembly Lines

- Smart robotics are used to automate the assembly process, reducing human error and increasing production speed.

- Robotic arms can precisely place components with high accuracy, leading to improved product quality.

- Automation of assembly lines also allows for continuous operation, leading to higher productivity levels.

Material Handling

- Robotic systems are employed for material handling tasks such as loading/unloading, sorting, and packaging.

- Smart robotics can lift heavy loads with ease, reducing the risk of injuries to human workers.

- Automated material handling systems ensure smoother workflow and faster turnaround times.

Quality Control

- Robotic vision systems are utilized for quality control inspections to detect defects or inconsistencies in products.

- Smart robotics can perform detailed inspections at a rapid pace, ensuring that only high-quality products reach the market.

- Automated quality control processes lead to improved product consistency and customer satisfaction.

Case Study: Tesla Gigafactory

The Tesla Gigafactory in Nevada is a prime example of successful integration of smart robotics in manufacturing. The factory utilizes a vast array of robotic systems for assembly, material handling, and quality control processes. This has significantly increased production efficiency and allowed Tesla to meet the growing demand for electric vehicles.

Technologies Driving Smart Robotics in Manufacturing

The latest advancements in smart robotics in manufacturing are powered by a combination of cutting-edge technologies that work together to enhance efficiency, precision, and adaptability in industrial settings.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning technologies are at the forefront of enhancing robotic capabilities in manufacturing. These technologies enable robots to learn from experience, adapt to changing environments, and make decisions autonomously. By leveraging AI and machine learning, smart robots can optimize production processes, predict maintenance needs, and improve overall productivity.

Sensors, Actuators, and IoT

Sensors, actuators, and the Internet of Things (IoT) play a crucial role in smart robotics for manufacturing. Sensors provide robots with the ability to perceive their environment, collect data, and respond to changes in real-time. Actuators enable robots to move with precision and perform tasks with accuracy.

IoT connectivity allows robots to communicate with other machines, systems, and humans, enabling seamless integration and collaboration in the manufacturing process.

Recent Technological Advancements

Recent advancements in technology have led to the development of more sophisticated smart robotics for manufacturing. Innovations in vision systems, collaborative robots, and advanced control algorithms have revolutionized the way robots operate in industrial environments. These advancements have resulted in increased flexibility, productivity, and safety in manufacturing processes, paving the way for the next generation of smart robotics solutions.

Challenges and Future Trends in Smart Robotics for Manufacturing

Implementing smart robotics in manufacturing processes comes with its own set of challenges that need to be addressed for successful integration and utilization. However, with the right solutions, these challenges can be overcome to maximize the benefits of smart robotics in manufacturing.

Challenges Faced in Implementing Smart Robotics in Manufacturing

- Lack of skilled workforce to handle and maintain smart robotics systems.

- High initial costs of implementing smart robotics technology.

- Integration of smart robotics with existing manufacturing processes and systems.

- Cybersecurity risks associated with connected smart robotics systems.

- Limitations in adaptability and flexibility of smart robotics for various manufacturing tasks.

Potential Solutions to Overcome Challenges

- Investing in training programs to upskill existing workforce in smart robotics technology.

- Exploring cost-effective options for smart robotics implementation, such as leasing or financing.

- Collaborating with experts in robotics and automation for seamless integration.

- Implementing robust cybersecurity measures to protect smart robotics systems.

- Developing modular and adaptable smart robotics solutions for diverse manufacturing needs.

Future Trends in Smart Robotics Technology for Manufacturing

- Increased use of artificial intelligence and machine learning in smart robotics for autonomous decision-making.

- Advancements in sensor technology for enhanced precision and efficiency in manufacturing processes.

- Integration of Internet of Things (IoT) for real-time monitoring and optimization of smart robotics systems.

- Development of collaborative robots (cobots) for safe human-robot interaction in manufacturing environments.

Contribution of Smart Robotics to Sustainable and Flexible Manufacturing Systems

Smart robotics technology plays a crucial role in creating more sustainable and flexible manufacturing systems by optimizing resource utilization, reducing waste, and enabling rapid adaptability to changing production requirements. With continuous advancements in smart robotics, the manufacturing industry is poised to achieve greater efficiency, productivity, and sustainability in the future.

Final Summary

In conclusion, the journey through the realm of smart robotics in manufacturing unveils a world of possibilities and advancements that promise to redefine the industry. From overcoming challenges to embracing future trends, smart robotics are poised to revolutionize manufacturing as we know it.

Expert Answers

How are smart robotics redefining manufacturing processes?

Smart robotics are introducing automation and precision to manufacturing, enhancing efficiency and productivity while reducing human error.

What industries are leveraging the latest smart robotics technology?

Industries such as automotive, electronics, and pharmaceuticals are at the forefront of adopting smart robotics for manufacturing processes.

What role do artificial intelligence and machine learning play in enhancing robotic capabilities?

Artificial intelligence and machine learning enable smart robotics to learn and adapt to different tasks, improving their versatility and performance.

How can smart robotics contribute to creating more sustainable manufacturing systems?

By optimizing processes and reducing waste, smart robotics can lead to more sustainable manufacturing practices that are environmentally friendly.