As smart factory automation solutions take the spotlight, this introduction invites readers into a realm of innovation and efficiency. Dive into a world where technology meets industry, promising a journey filled with insights and possibilities.

Exploring the concept, benefits, and future prospects of smart factory automation solutions will paint a vivid picture of the transformative power they hold in the manufacturing landscape.

Overview of Smart Factory Automation Solutions

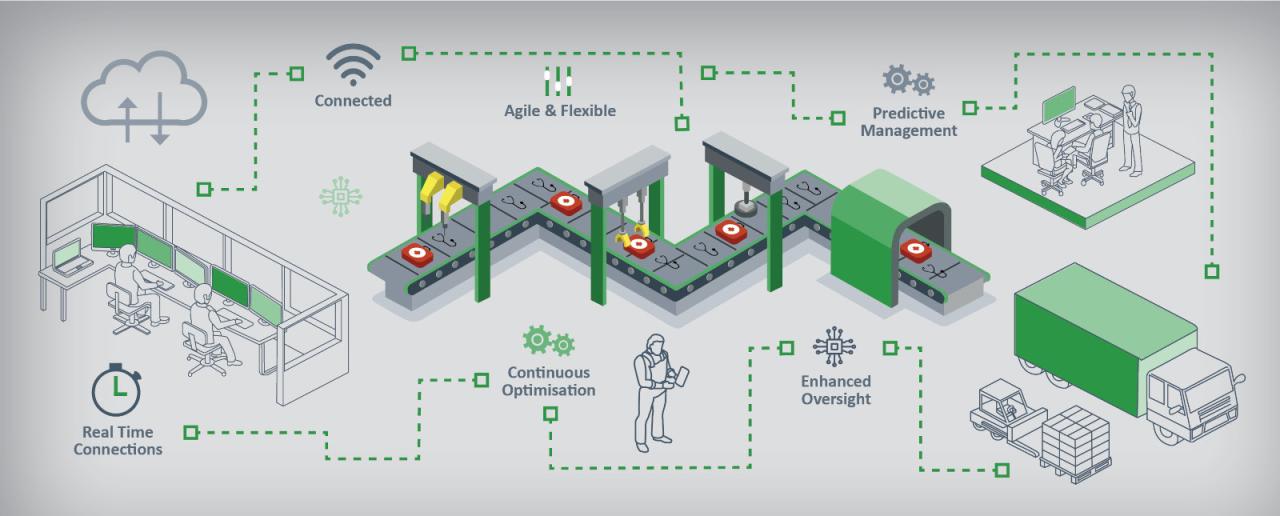

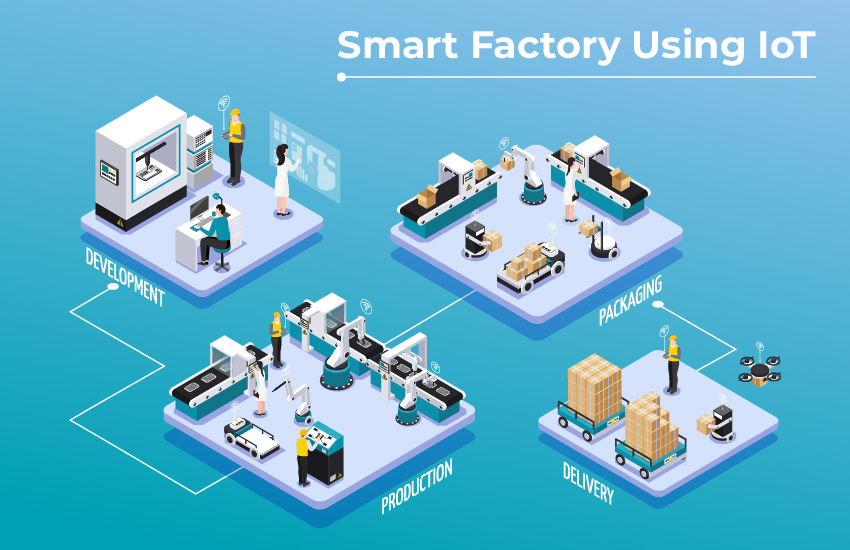

Smart factory automation solutions involve the use of advanced technologies such as IoT, AI, and robotics to optimize and automate manufacturing processes. These solutions aim to improve efficiency, productivity, and flexibility in factories by minimizing human intervention and maximizing operational performance.Implementing smart factory automation solutions in manufacturing processes offers a wide range of benefits.

This includes increased production speed, reduced labor costs, improved product quality, and enhanced safety measures. By streamlining operations and minimizing errors, companies can also experience higher output rates and quicker time-to-market for their products.Various industries can benefit from smart factory automation solutions, including automotive, electronics, pharmaceuticals, food and beverage, and more.

These industries can leverage automation technologies to enhance their production processes, reduce downtime, and meet increasing consumer demands with greater accuracy and precision.The role of IoT, AI, and robotics in smart factory automation solutions is crucial. IoT enables machines to communicate and share data in real-time, optimizing production schedules and predicting maintenance needs.

AI algorithms analyze this data to make informed decisions and improve overall efficiency. Robotics, on the other hand, perform repetitive tasks with precision and speed, freeing up human workers for more complex and creative assignments. Together, these technologies create a seamless and efficient manufacturing environment that drives business growth and competitiveness.

Key Technologies in Smart Factory Automation

Smart factory automation relies on a variety of key technologies to optimize manufacturing processes and increase efficiency. These technologies encompass a range of hardware and software solutions that work together to create a seamless and interconnected manufacturing environment.

Sensors and Data Analytics

Sensors play a crucial role in smart factory automation by collecting real-time data on various aspects of the manufacturing process. These sensors can monitor parameters such as temperature, pressure, humidity, and motion to ensure that the production line is running smoothly and efficiently.

Data analytics tools then analyze this data to identify patterns, trends, and potential issues, allowing for proactive maintenance and optimization of operations.

Connectivity and Interoperability

Connectivity is essential in smart factory automation, enabling different devices, machines, and systems to communicate with each other seamlessly. This connectivity, facilitated by technologies such as the Industrial Internet of Things (IIoT) and 5G networks, allows for real-time monitoring and control of manufacturing processes.

Interoperability ensures that all components of the smart factory ecosystem can work together efficiently, regardless of the manufacturer or technology used.

Software Platforms for Managing Automation

Software platforms serve as the backbone of smart factory automation, providing centralized control and monitoring of all manufacturing processes. Examples of software platforms used in smart factories include Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) systems, and Product Lifecycle Management (PLM) software.

These platforms enable manufacturers to streamline operations, track production in real-time, and make data-driven decisions to optimize efficiency and quality.

Implementation of Smart Factory Automation Solutions

Implementing smart factory automation solutions involves several key steps to ensure a successful integration into existing manufacturing systems. It is crucial to consider challenges, cost implications, and best practices to optimize the implementation process.

Steps in Implementing Smart Factory Automation Solutions

- Conduct a thorough assessment of current manufacturing processes and identify areas for automation.

- Choose the right automation technologies and tools based on the specific needs and goals of the factory.

- Develop a detailed implementation plan outlining timelines, resource allocation, and milestones.

- Train employees on how to operate and maintain the new automation systems effectively.

- Monitor and evaluate the performance of the automation solutions to make necessary adjustments for optimization.

Challenges and Considerations in Integration

- Compatibility issues between existing systems and new automation technologies.

- Data security and privacy concerns in interconnected smart systems.

- Resistance to change from employees who may fear job displacement due to automation.

- Ensuring seamless communication and collaboration between different automated processes.

Cost Implications of Adopting Smart Factory Automation Solutions

Investing in smart factory automation solutions can lead to significant cost savings in the long run through increased efficiency, reduced labor costs, and minimized errors.

Best Practices for Successful Implementation

- Collaborate closely with automation vendors and experts for guidance and support throughout the implementation process.

- Involve employees in the planning and decision-making to foster buy-in and acceptance of the new technologies.

- Constantly monitor and analyze data from the automation systems to identify areas for improvement and optimization.

- Regularly update and upgrade automation technologies to stay current with advancements in the industry.

Future Trends in Smart Factory Automation

In the rapidly evolving landscape of smart factory automation, several trends are shaping the future of manufacturing processes. These trends are driven by technological advancements, changing consumer demands, and the need for increased efficiency and sustainability.

Impact of Industry 4.0

Industry 4.0, often referred to as the fourth industrial revolution, is playing a significant role in the evolution of smart factory automation. This concept emphasizes the integration of cyber-physical systems, IoT, cloud computing, and cognitive computing to create interconnected and intelligent manufacturing systems.

The impact of Industry 4.0 is driving the adoption of advanced automation technologies, data analytics, and real-time monitoring in smart factories.

AI and Machine Learning in Smart Factory Automation

The future of smart factory automation is closely intertwined with artificial intelligence (AI) and machine learning. These technologies enable machines and systems to learn from data, identify patterns, and make decisions without human intervention. AI and machine learning algorithms are being used to optimize production processes, predict maintenance needs, and improve overall efficiency in smart factories.

Sustainability and Green Initiatives

As environmental concerns continue to grow, sustainability and green initiatives are becoming key drivers of innovation in smart factory automation. Manufacturers are focusing on reducing energy consumption, minimizing waste, and adopting eco-friendly practices in their production processes. Smart factory automation solutions are incorporating sustainable technologies such as energy-efficient equipment, renewable energy sources, and waste recycling systems to create more environmentally friendly manufacturing operations.

Ending Remarks

In conclusion, smart factory automation solutions pave the way for a future where precision, speed, and sustainability converge to reshape the industrial landscape. Embrace the possibilities, and embark on a journey towards enhanced productivity and efficiency in manufacturing processes.

Essential Questionnaire

What are the key technologies used in smart factory automation solutions?

The key technologies include IoT devices, AI algorithms, robotics systems, and data analytics tools.

What industries can benefit the most from smart factory automation solutions?

Industries such as automotive, electronics, pharmaceuticals, and consumer goods can significantly benefit from smart factory automation solutions.

What are the challenges of integrating smart factory automation solutions into existing manufacturing systems?

Challenges may include system compatibility issues, workforce training, cybersecurity risks, and initial setup costs.

How will AI and machine learning shape the future of smart factory automation?

AI and machine learning will enable predictive maintenance, autonomous decision-making, and adaptive production processes in smart factory automation.

What are some best practices for successful implementation of smart factory automation solutions?

Best practices involve thorough planning, gradual implementation, continuous monitoring, employee training, and adapting to technological advancements.