With smart GEP automation revolutionizing supply chain operations, this article delves into the transformative impact of automation technologies. From enhancing decision-making processes to optimizing efficiency, the integration of smart GEP automation is reshaping the way businesses manage their supply chains.

Importance of Smart GEP Automation in Supply Chain

Smart GEP automation plays a crucial role in enhancing the efficiency of supply chain operations. By incorporating automation tools and technologies, businesses can streamline their processes, reduce manual errors, and improve overall productivity.

Impact on Supply Chain Efficiency

Implementing smart GEP automation in the supply chain leads to smoother operations and faster turnaround times. Automated systems can handle repetitive tasks with precision, allowing employees to focus on more strategic activities. This efficiency ultimately translates to cost savings and improved customer satisfaction.

Enhanced Decision-Making Processes

Smart GEP automation provides real-time data analytics and insights that enable better decision-making in the supply chain. With access to accurate and up-to-date information, managers can make informed choices regarding inventory management, order fulfillment, and logistics planning. This proactive approach helps in reducing risks and optimizing resources effectively.

Key Benefits of Implementation

- Increased operational efficiency and productivity

- Reduced lead times and improved customer service

- Enhanced visibility and transparency across the supply chain

- Cost savings through optimized inventory management and logistics

- Mitigation of risks and errors through automated processes

Technologies Enabling Smart GEP Automation

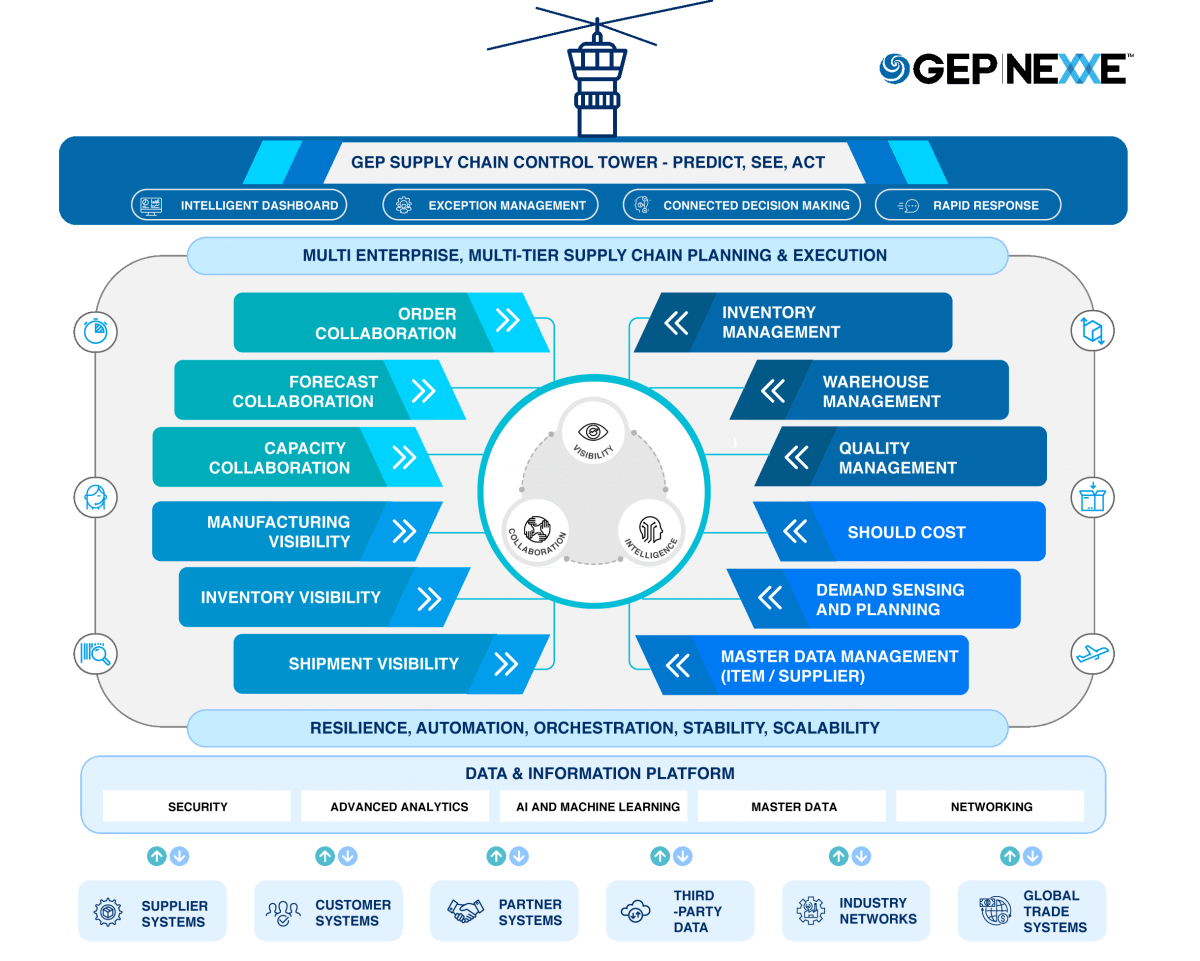

AI, IoT, and machine learning are key technologies driving smart GEP automation in the supply chain. These technologies enable organizations to streamline processes, improve efficiency, and make data-driven decisions.

Artificial Intelligence (AI)

AI plays a crucial role in smart GEP automation by enabling predictive analytics, demand forecasting, and intelligent decision-making. AI algorithms can analyze large datasets to identify patterns, optimize inventory levels, and automate repetitive tasks, such as order processing and supplier selection.

Internet of Things (IoT)

IoT devices, such as sensors and RFID tags, provide real-time visibility into the supply chain. By collecting and transmitting data on inventory levels, temperature, and location, IoT technology helps organizations track and monitor goods throughout the entire supply chain. This data can be used to optimize routes, prevent stockouts, and improve overall supply chain efficiency.

Machine Learning

Machine learning algorithms can analyze historical data to identify trends, predict demand, and optimize inventory levels. By continuously learning from new data, machine learning models can adapt to changing market conditions and make accurate forecasts. This enables organizations to reduce stockouts, minimize excess inventory, and improve overall supply chain performance.

Data Analytics

Data analytics plays a crucial role in optimizing smart GEP automation solutions by transforming raw data into actionable insights. By analyzing data from various sources, organizations can identify inefficiencies, optimize processes, and make informed decisions. Data analytics also enables organizations to track key performance indicators, monitor supplier performance, and improve overall supply chain visibility.

Challenges of Implementing Smart GEP Automation

Implementing smart GEP automation in the supply chain can be a complex process that comes with its own set of challenges. Organizations may face various obstacles when integrating these technologies into their operations, which can hinder the successful adoption of smart GEP automation.

It is important to address these challenges proactively to ensure a smooth and efficient implementation process.

Integration Challenges

One of the common challenges organizations face when implementing smart GEP automation is the integration of these technologies with existing systems. Compatibility issues between different software platforms and hardware devices can arise, leading to delays in the implementation process. It is crucial to ensure seamless integration to maximize the benefits of smart GEP automation.

- Lack of Standardization: Different vendors may use proprietary technologies that are not easily compatible with each other.

- Data Migration: Moving data from legacy systems to new automation platforms can be complex and time-consuming.

- Training and Skill Development: Employees may require training to effectively utilize smart GEP automation tools, which can be a resource-intensive process.

Risks Associated with Adoption

In addition to integration challenges, there are potential risks associated with the adoption of smart GEP automation technologies. These risks can impact the efficiency and effectiveness of supply chain operations if not managed properly. It is important for organizations to be aware of these risks and take proactive measures to mitigate them

Security Vulnerabilities: Automation systems can be susceptible to cyber threats, putting sensitive supply chain data at risk.

Dependency on Technology: Overreliance on automation tools without proper backup plans can lead to disruptions in case of system failures.

Cost Overruns: Implementing smart GEP automation can be costly, and organizations may face budget constraints during the implementation phase.

Strategies for Overcoming Obstacles

To overcome the challenges associated with implementing smart GEP automation effectively, organizations can adopt certain strategies to streamline the process and ensure successful integration.

- Conduct a Comprehensive Assessment: Evaluate existing systems and processes to identify areas that can benefit from automation.

- Collaborate with Technology Partners: Work closely with vendors and technology experts to ensure smooth integration and resolve compatibility issues.

- Invest in Employee Training: Provide training and upskilling opportunities to employees to enhance their technical capabilities and maximize the benefits of automation.

Case Studies on Successful Smart GEP Automation Implementation

Implementing smart GEP automation in the supply chain has proven to be beneficial for various companies. Let's explore some real-world examples of successful implementation and the improvements achieved.

Company A: Streamlining Procurement Processes

- Company A integrated smart GEP automation tools to streamline their procurement processes.

- By automating repetitive tasks such as purchase order processing and vendor management, Company A improved efficiency and reduced manual errors.

- The implementation resulted in a significant decrease in procurement cycle times and cost savings.

Company B: Enhancing Supplier Collaboration

- Company B utilized smart GEP automation to enhance collaboration with their suppliers.

- Automated communication channels and real-time data sharing improved visibility and transparency in the supply chain.

- As a result, Company B experienced better inventory management, reduced lead times, and improved supplier relationships.

Lessons Learned and Best Practices

- Effective change management is crucial when implementing smart GEP automation to ensure smooth transition and adoption.

- Companies should prioritize data accuracy and integration to maximize the benefits of automation tools.

- Continuous monitoring and evaluation of automated processes are essential for identifying areas of improvement and optimization.

Final Conclusion

In conclusion, the adoption of smart GEP automation presents a promising future for supply chain management. As organizations navigate challenges and embrace innovative technologies, the potential for growth and optimization is limitless.

FAQ Insights

How does smart GEP automation impact supply chain efficiency?

Smart GEP automation streamlines processes, reduces errors, and enhances overall operational efficiency in the supply chain.

What are the key benefits of implementing smart GEP automation in supply chain management?

Benefits include improved decision-making, cost savings, enhanced visibility, and increased productivity.

What technologies drive smart GEP automation?

Technologies such as AI, IoT, and machine learning play a crucial role in enabling smart GEP automation in the supply chain.

What are some common challenges faced when integrating smart GEP automation?

Challenges include data security concerns, workforce resistance to change, and integration complexities.

Can you provide examples of companies successfully implementing smart GEP automation?

Companies like Amazon, Walmart, and UPS have effectively leveraged smart GEP automation to optimize their supply chain operations.